Large tray sealing machine

The Tramper S-5100 is a large fully automatic tray sealing machine, which is equipped with servo controlled drives. The machine has a compact and extremely robust construction and, with its stainless steel design, fully complies with the demanding hygienic standards within the food industry. In addition, the tray sealer is characterized by excellent ease of use and high achievable capacities.

The tray sealing machine is suitable for processing almost any sealable packaging within the range of 500 x 1,000 mm. The S-5100 lends itself to both single and double lane tray sealing applications. The desired setup is formed by a basic version of the tray sealing machine, which can be fitted with a variety of options.

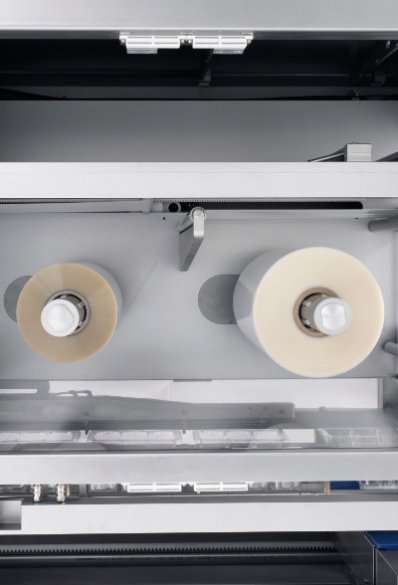

Furthermore, the tray sealing machine is standardly equipped with a servo controlled film transport system with break detection and a double film unwinding reel.

Features of the S-5100

Quick changeover time

Large sealing range

User-friendly

Quick changeover time

Large sealing range

User-friendly

Walking beam

The tray sealing machine is standardly equipped with an infeed conveyor with a length of approximately 4,000 mm. The infeed system is designed as a walking beam transport system with a stroke length of 1050 mm, which transports the trays step-by-step and accurately positions the trays. The movement of the walking beam transport system is servo driven and equipped with easily exchangeable tooling for changeovers between different tray sizes.

The transport speed of the infeed conveyor can be freely programmed per product via the controls of the sealing machine. Optionally, an inliner at the end of the tray sealing machine combines the two lanes of trays into a single lane.

Specifications of the tray sealer

- Sealing range: 1000 x 500 x 130 mm (LxWxH)

- Capacity: up to 14 cycles per minute

- Suitable for the sealing of products in liquid and solid form

- Prepared for Modified Atmosphere Packaging

- Suitable for single and double lane packaging

- Further automation with a tray denester, filling station and lidding system

- Suitable for complete built-in integration of labelling machine and printer

- Can be equipped with an integrated labelling machine and printer

- Standardly equipped with double film reel for quick film changes

This product is widely used in these industries